Motor Fuel Injection: A Innovation for Efficient and Safe machines

Introduction:

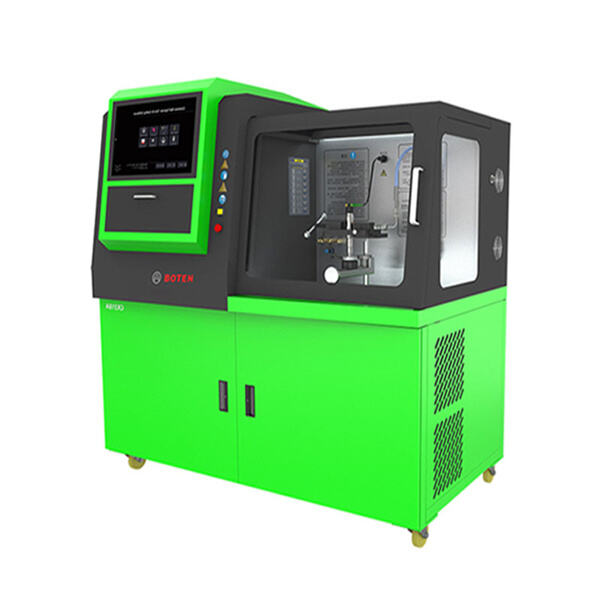

Motor Fuel Injection is a new tech has revolutionized the real way engines work, just like the Boten's product called diesel fuel injection pump tester. It is a process that involves mixing fuel and atmosphere in a engine to create a combustible mixture. The combination is then ignited to produce combustion and power. Fuel injection has many advantages over conventional carburetor engines, making it a popular preference usage in different applications.

Motor fuel injection has many benefits over traditional engines, identical to unit injector built by Boten. Very advantages that are significant better fuel effectiveness. Fuel injection brings precise amounts of fuel to the motor at the right time reducing fuel and waste. Additionally, fuel injected engines produce less air pollution, making them environment-friendly.

Gas injection is an innovation that aims to improve engine safety and gratification, as well as the Boten's unit injector. In traditional carburetor engines, fuel and air mix randomly in the carburetor, making it difficult to control fuel movement and combustion. The fuel is delivered directly to the engine in a controlled motor making it easier to manage and get a handle on in fuel injected engines. This also reduces the threat of engine fires and explosions, making fuel injection a safer option.

Using fuel injection in an engine requires some basic knowledge of system, same with the electronic fuel injection system by Boten. Gas injection systems use electronic fuel injectors that spray fuel into the engine in a real controlled way. The system works in collaboration with other engine components such as sensors, fuel pumps, and fuel filters. To use fuel injection, one specifications to ensure that all components come in good working condition plus the operational system is well maintained.

Maintaining a Motor Fuel Injection is crucial for optimal engine gratification and longevity, the same as Boten's hydraulic test stand. Regular maintenance and servicing help engine breakdown and improve efficiency. It can also be essential to use high-quality fuel replace worn-out parts regularly to ensure a smooth running engine. Always consult a expert mechanic fuel injection system repair and service.

CR1016 multi-functional common rail test bench designed by BOTEN is able to test Motor fuel injectionrail injectors, common rail pumps, HEUI injectors as well as oil pumps, EUI as well as EUP, also provides additional testing requirements. BOTEN's CR918S series, CR718 the CR518, CR518 and the CR318 series all loved by their customers. are always there to assist you with accurate professional testing throughout your diesel system service.

BOTEN has always been firm believer in the independent development and research and manufacturing common rail test benches, continually improve quality and Motor fuel injectionof equipment. have a lot of experiences with diesel systems. offer professional services and products that include maintenance techniques, training for service provision equipment components. clients have become accustomed to trusting adoring our products services.

BOTEN authorized dealers authorized dealers can provide timely top-quality service customers who have purchased an BOTEN test bench. can identify problems with equipment on internet remotely offer prompt repair and maintenance advice. We will provide best Motor fuel injectionsupport, regardless of the fact that your equipment is covered by warranty.

BOTEN founded in 1997. We have more than 20 years' Motor fuel injectiondiesel engines. team is working design an all-purpose rail test bench that includes more features functions, from the point view users. BOTEN products are designed with care by R D team and continually polished to ensure they're compatible with the most recent technology performance. Boten Common Rail Test Bench Maintenance Tools, other products support industry, service range to a wide range customers both the home and abroad and are striving to be one the leaders in fuel systems!

Copyright © Boten Testing Equipment(Suzhou)Co.,Ltd. - Privacy Policy